Introduction to Spoon Manufacturing

A spoon may seem simple, but its production involves multiple industrial steps. From raw materials to final polishing, each stage ensures durability, hygiene, and comfort.

Raw Materials Used for Spoons

Most spoons are made from stainless steel, aluminum, or plastic. Stainless steel is preferred for its strength and resistance to corrosion.

Metal Sheet Preparation

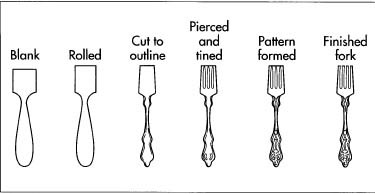

Stainless steel is melted and rolled into thin sheets. These sheets are cut into flat spoon shaped blanks.

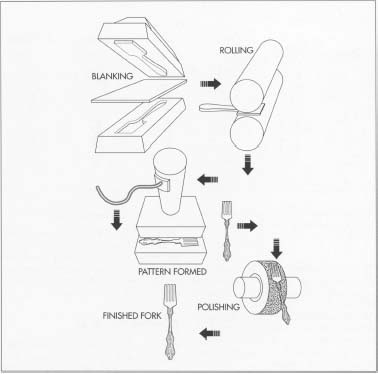

Stamping and Forming Process

The blanks are pressed using high pressure stamping machines. This creates the bowl and handle shape of the spoon.

Annealing for Strength

After stamping, spoons undergo annealing. This heat treatment relieves internal stress and improves strength.

Trimming and Smoothing

Excess metal is trimmed from the edges. The surface is smoothed to eliminate sharp areas.

Polishing and Finishing

Spoons are polished using mechanical buffers to achieve a shiny finish. Some are coated or engraved for decoration.

Quality Inspection

Each spoon is inspected for shape, weight, and surface quality to meet safety standards.

Packaging and Distribution

Finished spoons are cleaned, packaged, and shipped to retailers and manufacturers worldwide.

The spoon manufacturing process combines precision engineering with material science to create a simple yet essential tool.