Magnets play a crucial role in modern technology. They are found in electric motors, speakers, generators, medical equipment, and everyday household devices. While magnets may seem simple, the magnet manufacturing process involves precise material selection and advanced industrial techniques.

Magnets are generally classified into permanent magnets and electromagnets. This article focuses on the manufacturing process of permanent magnets, which retain their magnetic properties without an external power source.

Raw Materials Used in Magnet Making

The magnet making process begins with selecting suitable raw materials. Common materials include iron, nickel, cobalt, and rare earth elements such as neodymium and samarium.

Different combinations of these materials produce magnets with varying strength, durability, and resistance to heat. Neodymium magnets, for example, are known for their exceptional magnetic strength despite their small size.

Material Preparation and Alloying

Once the raw materials are selected, they are melted together in controlled furnaces to form an alloy. Precise temperature and composition control is critical, as even small variations can affect magnetic performance.

After melting, the alloy is cooled and solidified. In some cases, the solid material is crushed into fine powder to prepare it for shaping. Powder based manufacturing is common for high performance magnets.

Shaping the Magnet

There are several methods used to shape magnets, including pressing, sintering, and casting. In powder metallurgy, the powdered alloy is placed into molds and compressed under high pressure.

The compressed material is then sintered at high temperatures. This process bonds the particles together, increasing strength and density. Casting methods, on the other hand, involve pouring molten alloy into molds to create specific shapes.

Magnetization Process

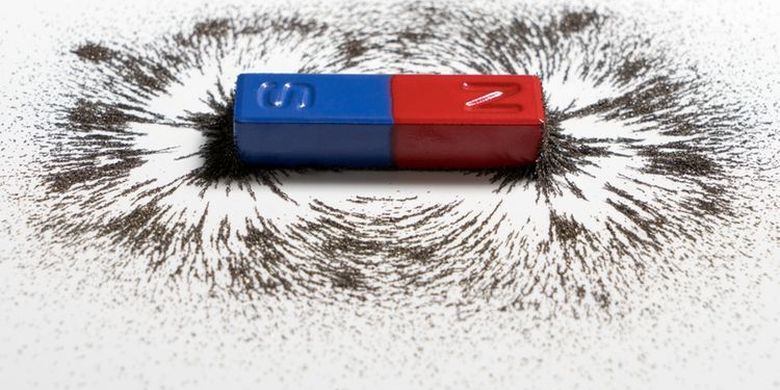

At this stage, the shaped material is not yet magnetic. Magnetization occurs when the material is exposed to a strong magnetic field. This aligns the magnetic domains within the material, giving the magnet its permanent magnetic properties.

Specialized magnetizing equipment is used to ensure uniform magnetization. The strength of the magnetic field and exposure time are carefully controlled.

Heat Treatment and Stabilization

Some magnets undergo heat treatment to improve stability and performance. Heat treatment helps relieve internal stresses and enhances resistance to demagnetization.

This step is especially important for magnets used in high temperature environments, such as automotive engines and industrial machinery.

Surface Coating and Protection

Many magnets are vulnerable to corrosion, especially those containing iron. To protect them, a surface coating is applied. Common coatings include nickel, zinc, epoxy, or plastic.

The coating not only improves durability but also enhances appearance and makes magnets safer to handle in consumer products.

Quality Control and Testing

Before magnets are released to the market, they undergo strict quality control tests. These tests measure magnetic strength, dimensional accuracy, and resistance to environmental factors.

Advanced testing equipment ensures that each magnet meets industry standards and performs reliably in its intended application.

Applications of Manufactured Magnets

Manufactured magnets are used across a wide range of industries. They are essential components in renewable energy systems, electric vehicles, data storage devices, and medical imaging equipment.

As technology advances, the demand for stronger and more efficient magnets continues to grow, driving innovation in magnet manufacturing techniques.

The magnet manufacturing process is a highly technical operation that combines materials science and precision engineering. From raw material selection to final magnetization, each stage plays a vital role in creating powerful and reliable magnets. Understanding this process reveals how invisible magnetic forces are carefully engineered to support modern life.