Introduction to Plastic Manufacturing

Plastic is one of the most widely used materials in the modern world. It appears in packaging, electronics, vehicles, and household goods. The process of making plastic involves chemistry, engineering, and industrial precision.

Raw Materials Used in Plastic Production

Most plastics are made from fossil fuels, primarily crude oil and natural gas. These resources contain hydrocarbons that can be transformed into polymers, the building blocks of plastic.

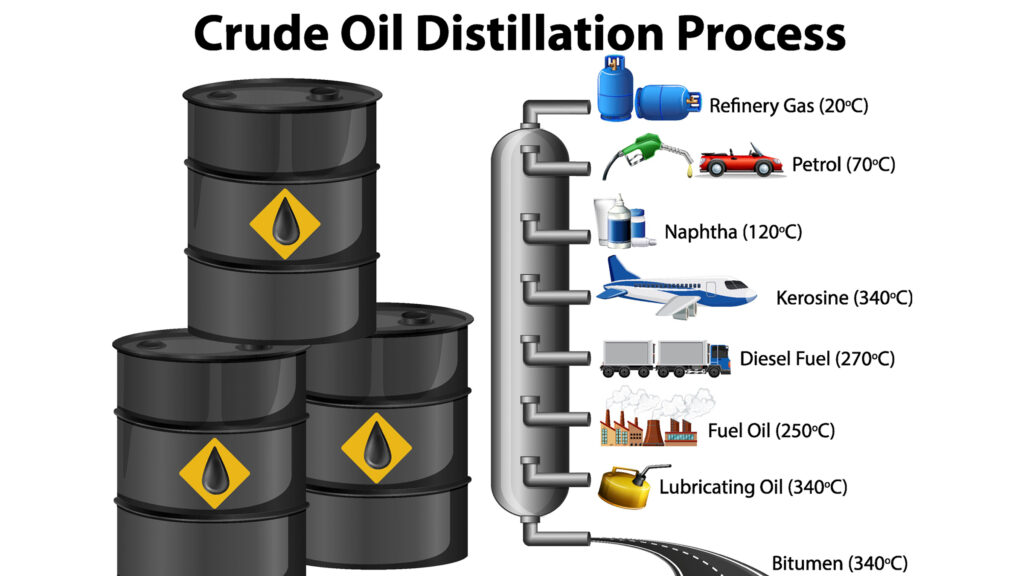

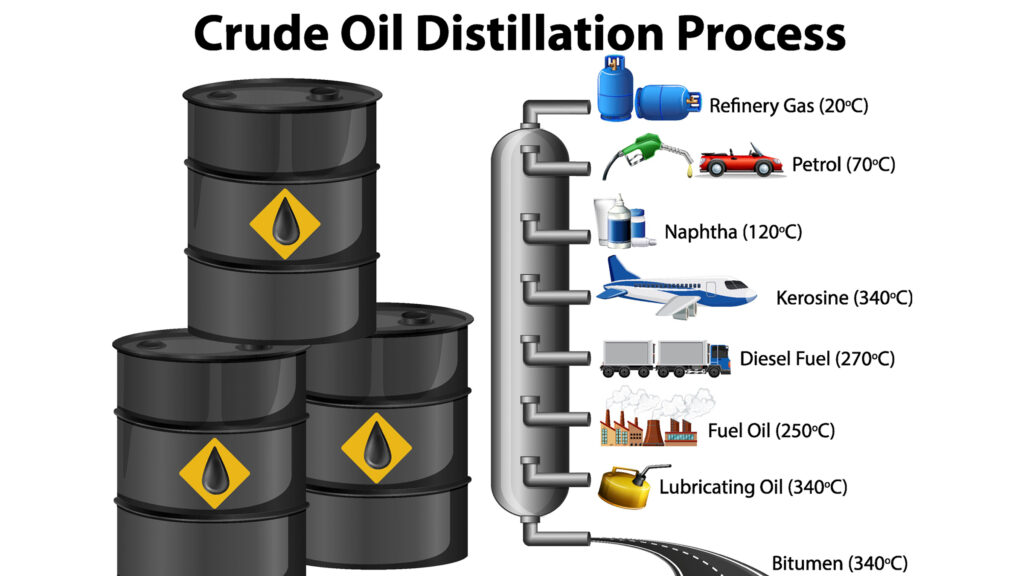

Refining Crude Oil into Feedstock

Crude oil is first refined in oil refineries. During this process, oil is heated and separated into fractions. One important fraction is naphtha, which is later used to create plastic materials.

Cracking Process and Monomer Production

Naphtha undergoes a process called cracking, where heat breaks large hydrocarbon molecules into smaller ones such as ethylene and propylene. These molecules are known as monomers.

Polymerization Process

Monomers are chemically bonded together through polymerization. This creates long chains called polymers, which give plastic its strength and flexibility.

Forming Plastic Pellets

The polymer is cooled and cut into small pellets. These pellets are the raw material used by manufacturers to create plastic products.

Shaping Plastic Products

Plastic pellets are melted and shaped using processes such as injection molding, extrusion, and blow molding. Each method is used for different types of products.

Final Products and Quality Control

Once shaped, plastic items are cooled, inspected, and packaged. Quality control ensures durability, safety, and consistency.

Plastic production is a complex process that transforms raw fossil fuels into versatile materials used worldwide.